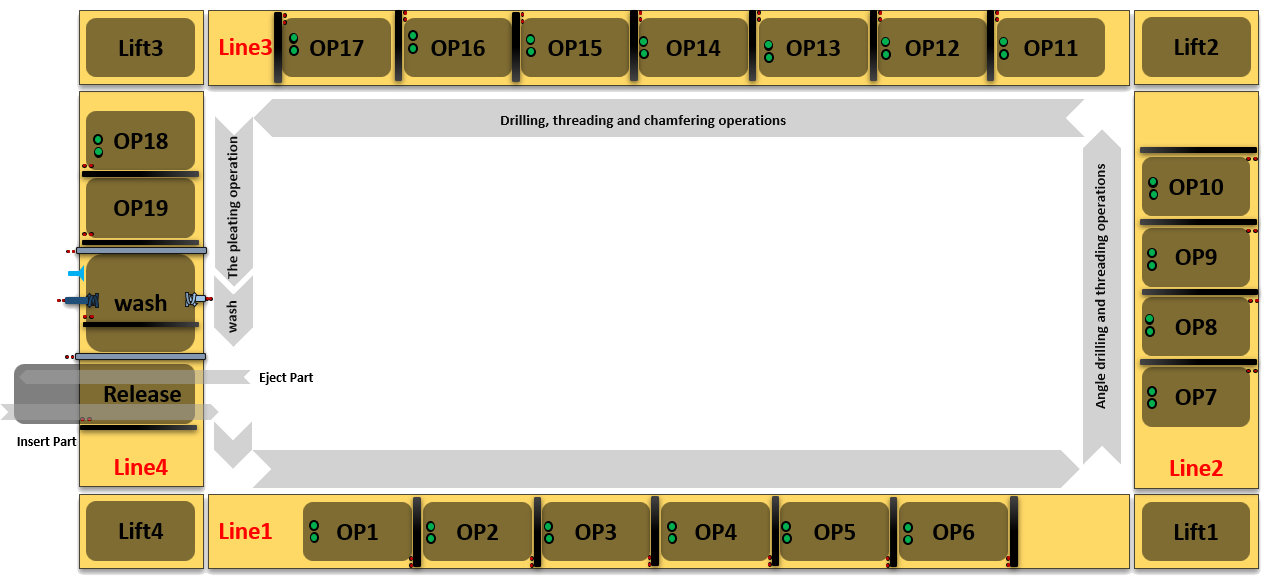

Car Caliper Product Line

Description

A set of machines for machining, drilling, threading and pleating of the car clipper.

This operation covers the calipers of 3 cars and left and right calipers were installed for each car.

Stages of the work cycle

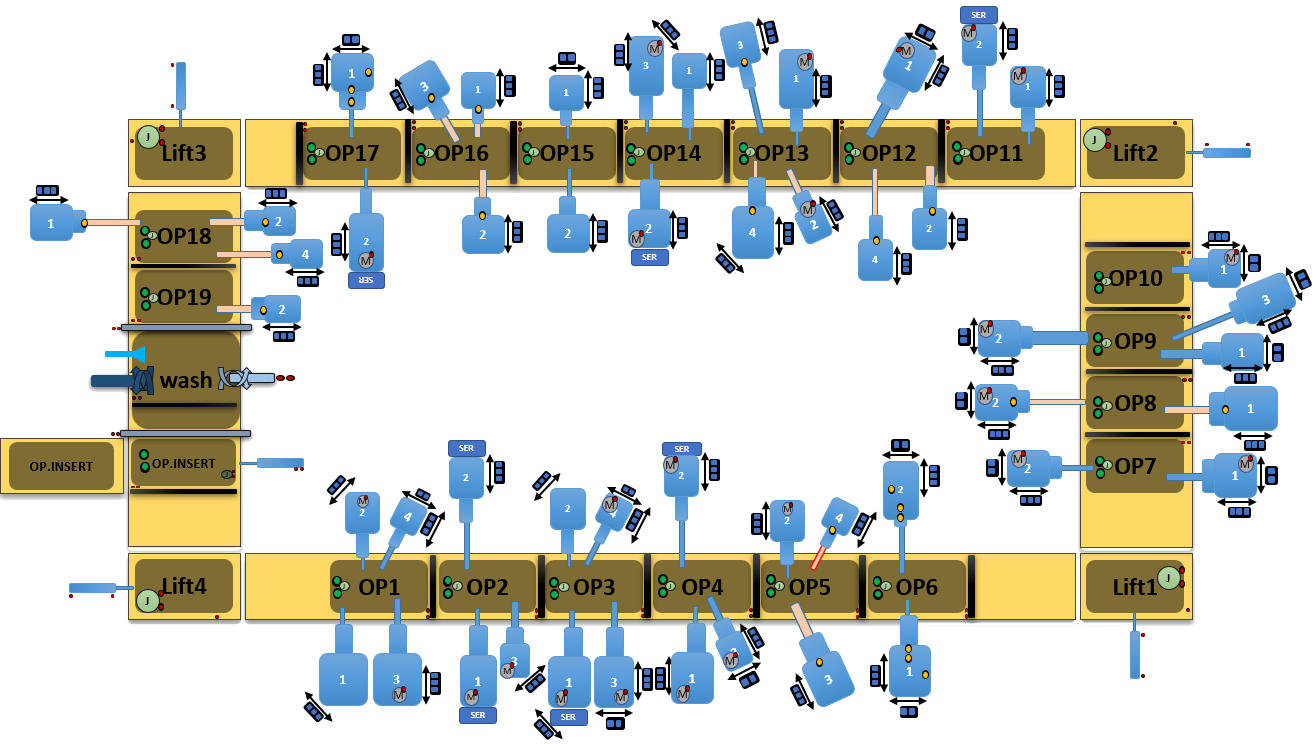

- Release Stage: The entry and exit operation of the fixture is to be moved by the pneumatic jack system.

- Lift 4 stage: It carries out the operation of transferring fixtures from conveyor line 4 to line 1.

- Line 1: Hard machining operations take place in units OP1, .., OP6.

- Lift 1 stage: It carries out the operation of transferring fixtures from conveyor line 1 to line 2.

- Line 2: Angle drilling and threading operations are carried out in stations OP7, .., OP10.

- Lift 2 stage: It carries out the operation of transferring fixtures from conveyor line 2 to line 3.

- Line 3: Drilling, threading and chamfering operations are carried out in stations OP11, .., OP17.

- Lift 3 stage: It carries out the operation of transferring fixtures from conveyor line 3 to line 4.

- Line 4: The pleating operation takes place at station OP18 and OP19.

- Washing stage: Fixtures and parts are washed in this station.

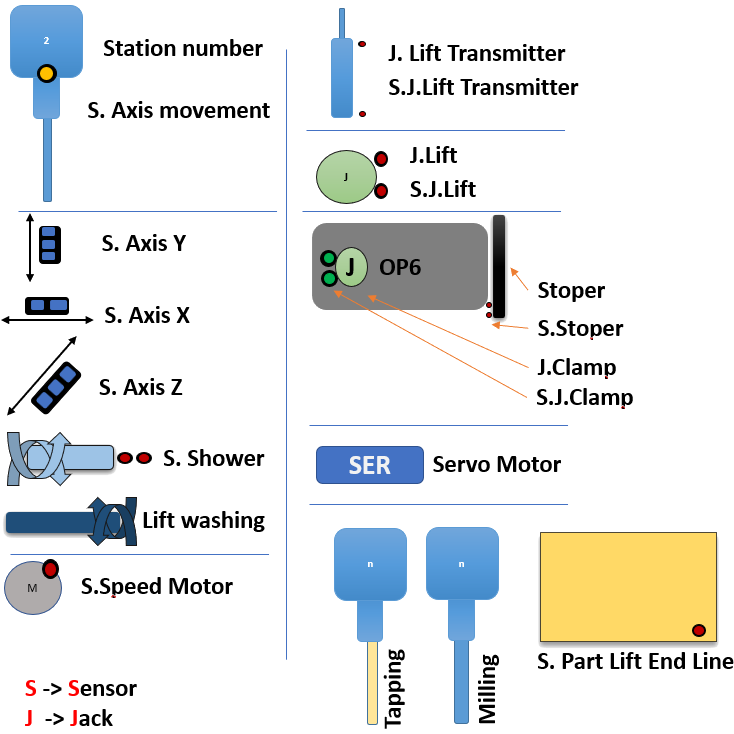

Additional description of station

- In each line, after the fixtures are stepped by the jack, the clamp operation is performed.

- Each station has 1 to 4 operating devices.

- The operation of these devices may be done in the direction of axis Y, axis X and Y, axis Z and Y or axis Z.

- There is a tool health detection sensor on drilling and threading tools.

- All the devices are connected to each other through Ethernet network, in case of an error, the necessary operations are performed simultaneously.