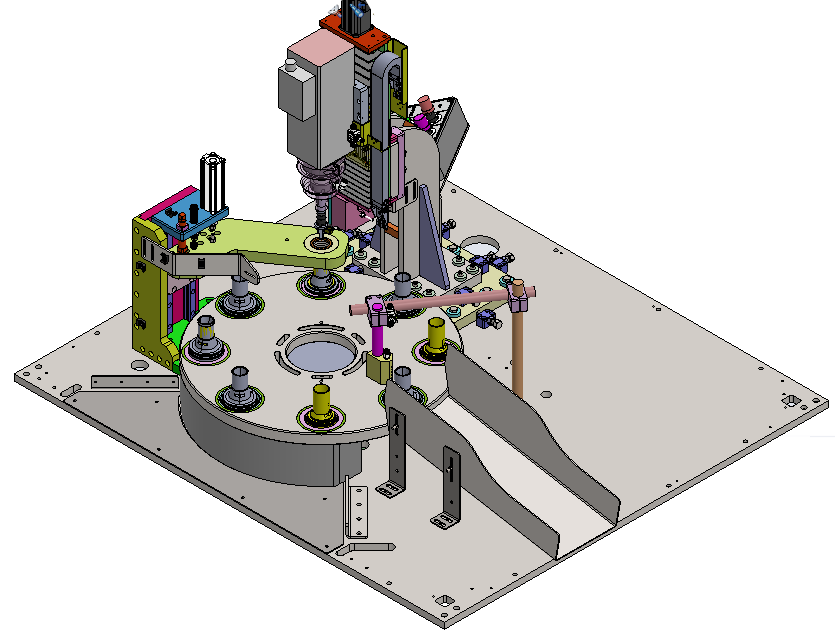

Booster valve machining

Car booster valve needs high precision machining, also its surface must be polished for car brake. Therefore, it was designed to increase the quality and standardize the production of automatic machining equipment.

Working steps of milk machining

It has four work steps:

- Insert part: At this stage, the operator places the number of three pieces in position.

- Machining: At this stage, the piece is machined from the top and bottom.

- Cleaning: At this stage, positive pressure from above and vacuum from below removes the pleats in the part.

- Eject Part: At this stage, the machined part is removed from the machine.

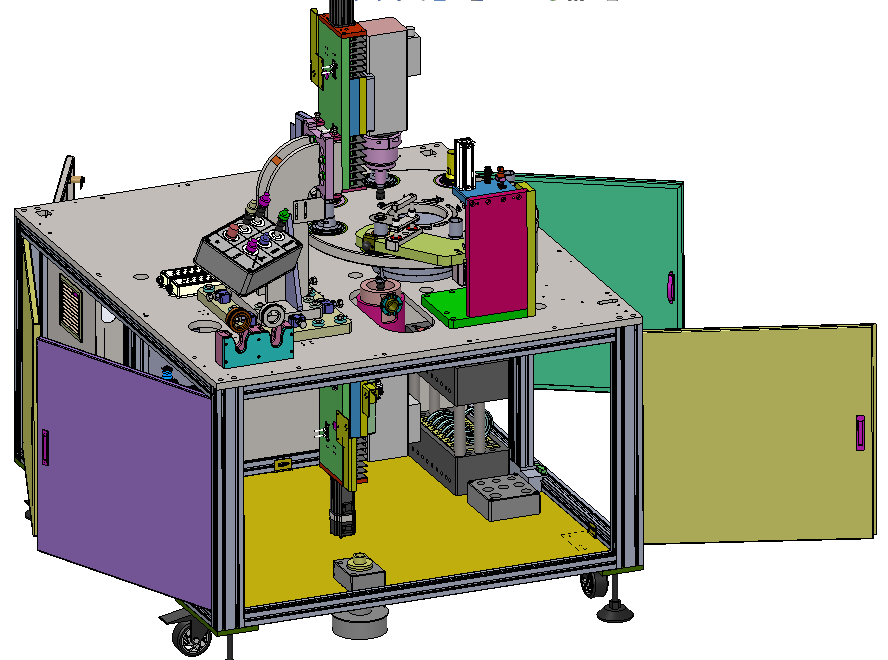

Features and capabilities of the device:

- Machining accuracy: 0.02 mm.

- Number of programs: 100 program.

- Stage Ability: Ability to enable and disable operators in the program.

- Self test: Yes.

- Tool health test: Automatic tool health test.

- Tools check: Testing the correctness of the tool installation.

- Protection program: Prevent tools from colliding, avoid dangerous settings.

- Cycle time: Ability to record program with selected cycle time.